TL;DR

Inefficient routing is silently draining your margins. Field service contractors waste 10-15 hours weekly on unnecessary travel due to poor route planning, costing $13,000-$15,000 annually per technician in lost productivity and fuel. Routing software FSM with AI-powered scheduling cuts travel time by 15-25%, enables technicians to complete 1-2 additional jobs daily, and dramatically improves cash flow. For Twin Falls contractors servicing rural Idaho territories—from Jerome to Burley to Kimberly—smart routing isn’t a luxury, it’s a survival necessity. This guide explains how AI scheduling transforms field operations with data-backed insights and practical implementation steps.

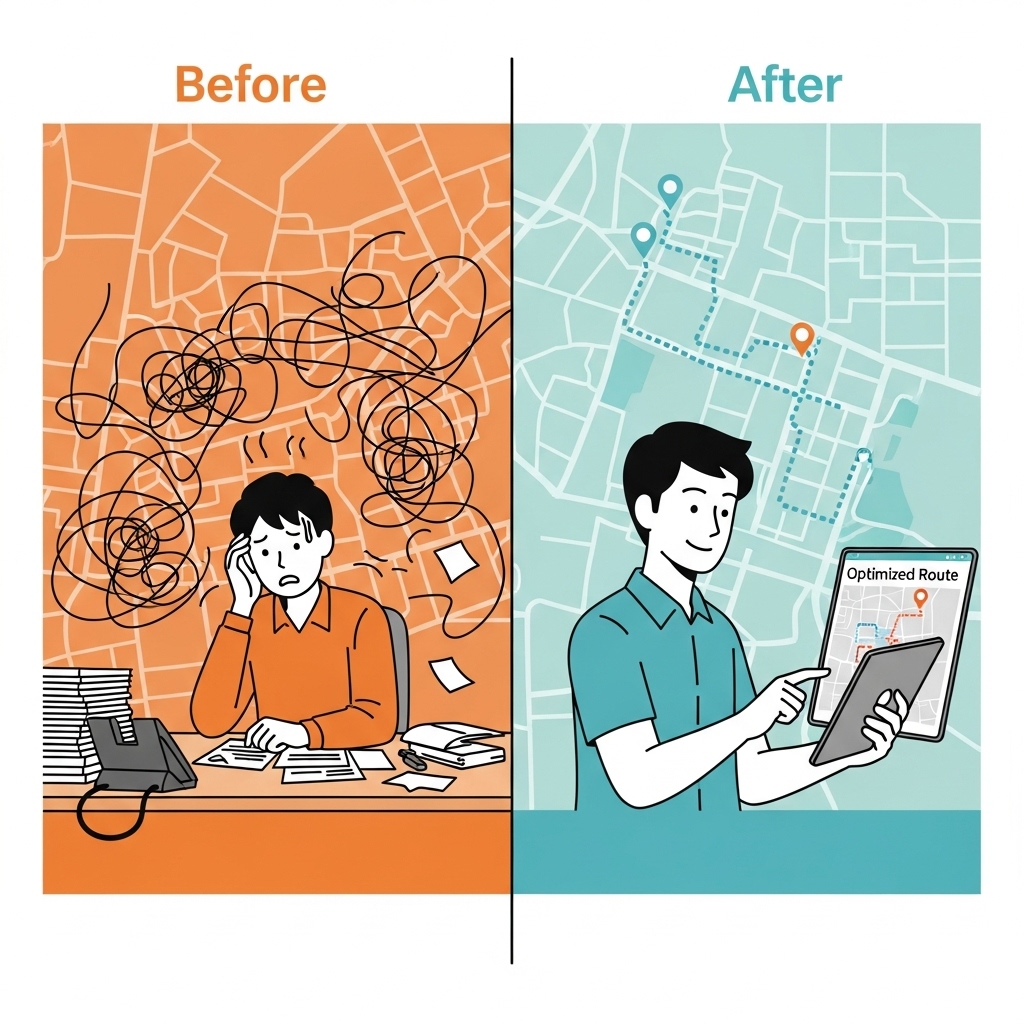

It’s 8:00 AM on a Thursday morning in Twin Falls. Your HVAC technician heads out for his first call in Jerome, 20 miles west. At 11:00 AM, he’s dispatched to Burley—40 miles east, back through Twin Falls. His 2:00 PM appointment? Kimberly, just 10 miles from Jerome where he started. By day’s end, he’s logged 120 miles in his truck and completed just three jobs.

Now imagine this: the same three jobs, sequenced intelligently—Jerome at 8:00 AM, Kimberly at 10:30 AM, Burley at 1:30 PM. Your technician drives 70 miles instead of 120, finishes by 3:30 PM, and has time for a fourth appointment before day’s end. That’s 50 fewer miles, one extra job, and significantly higher margins—all without working longer hours.

This is the power of routing software FSM (field service management)—AI-powered platforms that optimize scheduling, sequencing, and dispatch to minimize travel time and maximize revenue. For contractors operating in rural territories where drive times between Twin Falls, Jerome, Burley, and surrounding areas can consume 20-30% of each workday, intelligent routing isn’t just convenient—it’s the difference between profit and loss.

Let’s explore how modern routing technology transforms field service operations, backed by data, real-world scenarios, and practical implementation guidance.

The True Cost of Travel Time and Poor Routing

The Hidden Expense Eating Your Margins

Most contractors focus on obvious costs: labor rates, materials, equipment maintenance. But there’s a silent profit killer that rarely shows up on financial statements: wasted travel time.

Consider what happens when your technician spends an extra hour daily driving inefficient routes:

- Lost billable time: 5 hours weekly at $75/hour = $19,500 annually per technician

- Fuel costs: Extra 100 miles weekly at $0.60/mile (including fuel and vehicle wear) = $3,120 annually

- Opportunity cost: Jobs you can’t complete because technicians are stuck in trucks = $25,000-40,000 in lost revenue annually

According to research on field service productivity, travel time represents the greatest source of productivity leakage in field operations. The data is stark: reducing field worker travel time by just 10% per day can increase productivity by as much as one additional job per day.

For contractors in Southern Idaho, where service territories span vast rural areas, these inefficiencies multiply quickly. A plumbing company serving Twin Falls, Jerome, and Burley might have technicians driving 150-200 miles daily. If 30% of that mileage results from poor route sequencing, you’re burning $4,000-$5,000 annually per truck in unnecessary fuel alone—before accounting for the far more significant cost of lost productive time.

The Mathematics of Inefficient Routing

Let’s break down what inefficient routing actually costs a small contractor with three field technicians:

Current state (manual scheduling):

- 8 jobs per technician per week

- 25 hours worked, 10 hours driving (40% travel time)

- 300 miles driven weekly per technician

- Revenue: 8 jobs × $500 average = $4,000 weekly per tech

Optimized state (with routing software FSM):

- 10 jobs per technician per week (25% increase)

- 25 hours worked, 7 hours driving (28% travel time)

- 210 miles driven weekly per technician (30% reduction)

- Revenue: 10 jobs × $500 = $5,000 weekly per tech

Annual impact across 3 technicians:

- Additional revenue: $1,000/week × 50 weeks × 3 techs = $150,000

- Fuel savings: 90 miles/week × 3 techs × $0.60/mile × 50 weeks = $8,100

- Total annual benefit: $158,100

These aren’t theoretical numbers. Industry research shows that field service organizations implementing automated scheduling and route optimization see average productivity improvements of 20%, with some achieving even higher gains.

Why Manual Routing Fails in Rural Service Territories

Manual route planning—whether using spreadsheets, paper maps, or even basic GPS—breaks down under real-world complexity. Dispatchers juggling multiple variables (technician skills, job duration estimates, customer time windows, emergency calls, traffic conditions) simply cannot optimize as effectively as algorithms designed for this exact purpose.

In rural Idaho, this complexity intensifies. Consider the challenges:

- Variable drive times: The 30-minute drive from Twin Falls to Buhl becomes 45 minutes in winter weather or during harvest season traffic

- Last-minute changes: Customer cancellations or emergency calls require complete schedule reshuffling

- Technician availability: Skills, certifications, and on-hand parts vary by technician

- Geographic spread: Service areas spanning 50+ mile radiuses create exponential routing combinations

A dispatcher might create what looks like an efficient schedule at 7:00 AM, but by 10:00 AM, reality has rendered it obsolete. Without intelligent software constantly recalculating optimal routes based on real-time conditions, technicians spend hours driving back and forth across the same territory.

How AI-Powered Scheduling Changes the Game

The Intelligence Behind Modern Routing Software FSM

Routing software FSM brings together advanced algorithms, real-time data, and field service expertise to solve problems human dispatchers simply cannot manage at scale. These systems don’t just map routes—they orchestrate entire field operations with precision impossible through manual methods.

Here’s what distinguishes AI-powered scheduling from basic GPS or route mapping:

Multi-variable optimization: The software simultaneously considers dozens of factors: technician location, skillset, scheduled breaks, parts inventory, estimated job duration, customer preferences, traffic patterns, weather conditions, and appointment windows. It calculates thousands of potential schedule combinations in seconds and selects the mathematically optimal solution.

Dynamic real-time adjustments: When a customer cancels at 11:00 AM, the system immediately recalculates routes for all affected technicians, suggests reassignments, and updates everyone’s schedule automatically. What would take a dispatcher 20 minutes of phone calls happens in 30 seconds.

Predictive intelligence: The software learns from historical data. It knows that residential HVAC repairs in Jerome typically take 90 minutes, while commercial jobs in Burley average 2.5 hours. This precision prevents the domino effect of overly optimistic scheduling that leaves customers waiting and technicians rushing.

According to field service management research, artificial intelligence and mobility together increase field service agent productivity by 30-40%. This isn’t marginal improvement—it’s transformational change that enables contractors to complete significantly more work with existing resources.

From Reactive Dispatch to Proactive Orchestration

Traditional dispatching is reactive: a job comes in, you assign it to whoever seems available, and hope everything works out. AI scheduling is proactive orchestration that anticipates and prevents problems before they occur.

Consider how these systems handle a typical Tuesday:

Monday evening: The software reviews Tuesday’s scheduled appointments, analyzes optimal sequencing, and generates preliminary routes for each technician. It identifies potential conflicts (a 2-hour job scheduled with only 90 minutes before the next appointment) and flags them for dispatcher review.

Tuesday 6:00 AM: Routes are finalized and pushed to technician mobile apps. Each tech sees their day at a glance: job locations on a map, optimized driving sequence, customer information, and estimated completion times.

Tuesday 10:30 AM: A customer calls with an emergency. The system analyzes which technician can respond fastest without disrupting other appointments. It suggests reassigning a lower-priority job and provides the revised schedule to both affected technicians instantly.

Tuesday 2:00 PM: A job in Kimberly finishes 30 minutes early. The system identifies a nearby opportunity: a quote request from last week that hasn’t been scheduled. The dispatcher can assign it on-the-fly, and the technician has all customer details on his tablet within minutes.

This level of coordination is impossible with manual dispatching, especially as your business grows beyond 2-3 technicians.

Real-World Performance Gains

The productivity improvements from intelligent routing aren’t theoretical projections—they’re documented outcomes from field service operations that have made the transition.

Research on route optimization benefits shows that organizations implementing these systems typically see:

- 15-25% reduction in drive time as routes are sequenced geographically rather than chronologically

- 20-30% increase in daily job capacity from recovered time and better scheduling density

- 10-15% fuel cost savings from reduced unnecessary mileage

- Higher first-time fix rates because the right technician with the right parts arrives at each job

For a Twin Falls contractor with three trucks averaging 1.5 hours of daily drive time per technician, cutting travel by 20% means recovering 1.5 hours weekly per tech. That’s 4.5 hours across your team—enough for 3-5 additional service calls weekly, generating $75,000-$125,000 in additional annual revenue.

Even more valuable: technician satisfaction improves dramatically. Nobody enjoys spending 10+ hours weekly stuck in traffic when they could be working, learning, or home with family. Field service research shows that 80% of field service professionals believe mobile technology improves productivity and responsiveness, directly impacting job satisfaction and retention.

Key Metrics & Benefits to Track

Measuring What Matters: The KPIs That Drive Profitability

Implementing routing software FSM requires investment, so you need clear metrics to measure ROI and identify improvement opportunities. These are the essential KPIs every contractor should monitor:

Travel time per technician per day: Your baseline metric. Track average daily drive time before implementation, then measure weekly to confirm improvements. Target: 15-25% reduction within 90 days.

Jobs completed per technician per day: The ultimate productivity measure. More completed jobs equal more revenue without adding headcount. Target: 1-2 additional jobs daily per technician.

Fuel cost per technician per week: A straightforward financial metric that directly correlates with routing efficiency. Track both mileage and actual fuel spend. Target: 10-15% reduction.

First-time fix rate: Percentage of jobs completed without return visits. Good routing ensures technicians arrive with correct parts and adequate time. Target: above 85%.

Technician utilization rate: Billable hours divided by total available hours. According to field service best practices research, best-in-class service organizations achieve 81% or greater workforce utilization.

On-time arrival rate: Percentage of appointments where technicians arrive within the scheduled window. Optimized routing dramatically improves this metric because schedules reflect realistic drive times. Target: above 90%.

Calculating Your ROI

Let’s work through a practical ROI calculation for a small Twin Falls contractor considering routing software FSM:

Current state (3 technicians, manual scheduling):

- Weekly jobs: 24 (8 per tech)

- Weekly drive time: 30 hours total (10 per tech)

- Weekly miles: 900 (300 per tech)

- Fuel cost: $540 weekly ($0.60/mile)

- Annual fuel: $28,080

Projected state (with routing software FSM):

- Weekly jobs: 30 (10 per tech, 25% increase)

- Weekly drive time: 21 hours total (7 per tech, 30% reduction)

- Weekly miles: 630 (210 per tech, 30% reduction)

- Fuel cost: $378 weekly

- Annual fuel: $19,656

Annual financial impact:

- Additional revenue: 6 jobs/week × $500 × 50 weeks = $150,000

- Fuel savings: $8,424

- Software cost: -$3,600 (estimated $300/month)

- Net benefit: $154,824

This 43:1 return on investment assumes you’re simply completing more jobs with existing capacity. It doesn’t account for additional benefits: higher customer satisfaction, reduced technician turnover, ability to accept more work without hiring, competitive advantages from faster response times.

For contractors in rural areas like Southern Idaho where drive times represent significant operational overhead, these gains are even more pronounced. Research shows that reducing travel time by just 10% can increase productivity by one additional job daily. When your technicians regularly drive 150-200 miles daily, the savings compound rapidly.

Real-World Scenarios for Twin Falls & Southern Idaho Contractors

Scenario 1: The Geographic Clustering Win

The Situation: An electrical contractor in Twin Falls receives these morning appointments:

- 10:00 AM: Residential service call in Filer (12 miles south)

- 11:30 AM: Commercial estimate in Kimberly (8 miles east)

- 1:00 PM: Emergency repair in Jerome (20 miles west)

- 3:00 PM: Routine maintenance in Buhl (25 miles west of Twin Falls)

Manual routing approach: The dispatcher books appointments chronologically as they come in. The technician’s day: Twin Falls → Filer → Kimberly → Jerome → Buhl. Total driving: approximately 75 miles and 2.5 hours.

AI-optimized routing: The routing software FSM analyzes job locations and suggests: Twin Falls → Jerome → Buhl → Filer → Kimberly. By starting west and working east, the technician drives approximately 55 miles and 1.75 hours—saving 20 miles and 45 minutes.

Impact: That recovered 45 minutes allows the technician to handle a fifth appointment near Twin Falls at 4:30 PM. One day’s optimization adds $400-$500 in revenue and improves customer satisfaction through faster emergency response.

Scenario 2: The Last-Minute Cancellation Recovery

The Situation: A plumbing company has technicians scheduled throughout Southern Idaho. At 11:15 AM, a customer in Burley cancels a 12:00 PM appointment. The nearest technician is in Jerome, 40 miles away, with his next job scheduled for 3:00 PM in Twin Falls.

Manual dispatch response: The dispatcher notices the cancellation, calls the technician to inform him, and tries to find fill-in work. By the time phone calls are made and schedules adjusted, it’s 12:30 PM. The technician drives to Twin Falls for his 3:00 PM appointment, arriving by 1:00 PM with 2 hours of idle time.

AI-optimized response: The routing software FSM immediately alerts when the cancellation occurs. It analyzes all pending work orders and identifies three options:

- A quote request from two days ago in Burley (5 minutes from the cancelled job)

- A routine maintenance job in Jerome that could be moved up from Thursday

- A service call in Rupert (15 miles from Burley) that was scheduled for tomorrow

The system suggests Option 1, automatically sends job details to the technician’s mobile app, and updates the customer with an estimated arrival time. The technician completes the Burley quote, then proceeds to his Twin Falls appointment.

Impact: Zero idle time, an additional completed job, and improved customer service (the quote customer receives same-day service instead of waiting 3-4 days). Annual impact: capturing just 2-3 such opportunities weekly adds $50,000+ in revenue.

Scenario 3: The Multi-Technician Coordination Challenge

The Situation: An HVAC company serves Twin Falls and has expanded into Southern California. They have 4 technicians in Idaho and 2 in California. A commercial client with locations in both markets needs quarterly maintenance across all sites.

Manual coordination: The office manager manually coordinates schedules, trying to ensure both regions receive service within the same week. She spends hours on spreadsheets, makes multiple phone calls to customers confirming dates, and inevitably someone’s schedule changes, requiring complete rework.

Unified routing software FSM: The system manages both markets from a single dashboard. When the quarterly maintenance schedule is created:

- Idaho technicians are automatically assigned to Twin Falls, Jerome, Burley, and Kimberly locations based on their service territories

- California technicians receive assignments for their region

- All appointments are optimized geographically within each market

- Customers receive automated confirmation emails with specific dates and arrival windows

- If any schedule changes occur, the system recalculates affected routes and notifies everyone automatically

Impact: What took 6-8 hours of manual coordination now takes 30 minutes. The office manager can focus on customer service and business development rather than schedule Tetris. The company can confidently expand to additional markets knowing their systems scale efficiently.

For contractors operating across multiple locations or considering expansion, unified field service management platforms become essential infrastructure that enables growth without proportional increases in administrative overhead.

How to Implement Routing Software FSM in Your Business

Step 1: Audit Your Current Routing Processes

Before investing in new technology, you need baseline data to measure against. Spend 2-3 weeks tracking:

Travel metrics for each technician:

- Daily mileage driven

- Hours spent driving vs. working on jobs

- Number of jobs completed daily

- Instances of backtracking or inefficient routing

Scheduling challenges:

- How many schedule changes occur daily

- Average time dispatchers spend on schedule adjustments

- Missed appointment frequency

- Emergency call response times

Cost data:

- Weekly fuel consumption per vehicle

- Overtime hours caused by inefficient routing

- Jobs declined because capacity was maxed

Create a simple spreadsheet or use your existing GPS tracking (if you have it). You’re looking for patterns: Are technicians crossing the same territory multiple times daily? Are certain days consistently chaotic? How much time do dispatchers spend firefighting schedule issues?

A Twin Falls contractor might discover technicians are averaging 2 hours of drive time daily for jobs clustered within a 30-mile radius—clear evidence that better routing could recover 30-45 minutes per day.

Step 2: Set Clear, Measurable Targets

Based on your audit, establish realistic improvement goals:

Conservative targets (Year 1):

- Reduce average daily travel time by 15-20%

- Increase completed jobs per technician by 1-2 weekly

- Cut fuel costs by 10-15%

- Improve on-time arrival rate to 85%+

Aggressive targets (if your current routing is particularly inefficient):

- Reduce travel time by 25-30%

- Add 3-5 jobs weekly per technician

- Cut fuel costs by 20%

- Achieve 90%+ on-time arrivals

Share these targets with your team. Technicians need to understand why you’re implementing new software and how it benefits them (less time in trucks, more predictable schedules, less rushing).

Step 3: Choose the Right Routing Software FSM

Not all field service management platforms are created equal. Evaluate options based on:

Core routing capabilities:

- AI-powered route optimization (not just GPS mapping)

- Real-time route recalculation when schedules change

- Integration with your existing scheduling and dispatch systems

- Mobile apps for technicians with offline functionality

Field-specific features:

- Technician skill matching (sends the right tech to each job)

- Parts inventory tracking (ensures techs have what they need)

- Customer communication automation (appointment confirmations, ETA updates)

- Integration with invoicing and payment processing

Local considerations: For contractors in rural Idaho areas where cell service can be intermittent, offline capability is non-negotiable. Your technicians need to access schedules, job details, and navigation even when connectivity is limited. Choose mobile-first platforms with robust offline functionality.

Integration capabilities: The best routing software FSM doesn’t operate in isolation—it connects with your entire business ecosystem. Look for platforms that integrate operations (scheduling, dispatch, job tracking) with marketing and lead generation systems. For example, FieldServ AI handles field operations while LeadProspecting AI manages lead capture and customer communication. When these systems work together, website inquiries automatically become scheduled jobs without manual handoff—eliminating the gaps where opportunities disappear.

Contractors serious about building complete business systems should explore platforms designed to work together from the start. Programs like LeadProspecting AI’s Founders Club offer lifetime pricing on comprehensive marketing automation that integrates with operational systems—limited to the first 200 members who want to lock in founding rates.

Step 4: Pilot with One Territory or Team

Don’t attempt company-wide implementation on day one. Start with a controlled pilot:

Week 1-2: Setup and training

- Configure the software with your service area, technician profiles, and standard job types

- Train one dispatcher and 1-2 technicians on core functionality

- Run parallel systems (old and new) so nothing falls through cracks

Week 3-4: Live pilot

- Manage the pilot team exclusively through new routing software FSM

- Monitor daily: Are routes actually more efficient? Are technicians adapting well?

- Collect feedback: What’s working? What’s confusing?

- Measure against baseline: travel time, jobs completed, fuel consumption

Week 5-6: Evaluate and adjust

- Analyze pilot results against targets

- Address any issues or training gaps

- Decide on full rollout timeline

A Twin Falls contractor might pilot with the technician covering the Jerome-Buhl-Wendell territory while the other two continue with manual dispatching. This limits risk while demonstrating ROI before full commitment.

Step 5: Roll Out Company-Wide and Monitor Continuously

Once your pilot proves successful, expand to remaining technicians:

Rollout phase (2-3 weeks):

- Train all dispatchers and field technicians

- Migrate all customer and job data into the new system

- Establish new workflows for how jobs are assigned, updated, and completed

- Maintain support channels so team members can ask questions

Ongoing optimization (continuous):

- Review routing metrics weekly for first 90 days

- Identify patterns: Are certain technicians or territories underperforming expectations?

- Adjust system settings: job duration estimates, travel time calculations, service area boundaries

- Celebrate wins: When you hit efficiency targets, recognize the team’s adaptation

The most successful implementations treat routing software FSM as an operational system that requires continuous refinement, not a set-it-and-forget-it solution.

Conclusion: From Survival to Thriving

Every minute your technicians spend driving inefficient routes is a minute they’re not generating revenue, serving customers, or growing their skills. Every gallon of fuel burned unnecessarily is profit evaporating into the Idaho desert air. Every job you can’t complete because technicians are maxed out is an opportunity handed to competitors.

Routing software FSM with AI-powered scheduling transforms these losses into competitive advantages. When your technicians complete 20-30% more jobs with the same work hours, when your fuel costs drop 10-15%, when your customers consistently receive on-time service—you’re not just improving operations, you’re fundamentally changing what your business can achieve.

The mathematics are undeniable:

- 15-25% travel time reduction = 6-8 hours recovered weekly per technician

- 1-2 additional jobs daily = $150,000+ additional annual revenue for a 3-tech operation

- 10-15% fuel savings = $8,000-$10,000 annual cost reduction

- Higher customer satisfaction = more referrals, better reviews, sustained growth

For contractors servicing Twin Falls, Jerome, Burley, Kimberly, and rural Southern Idaho communities, where drive times between jobs can easily consume 20-30% of each workday, these improvements aren’t marginal gains—they’re survival necessities. Your competitors who adopt intelligent routing will complete more jobs, respond faster to emergencies, and operate at lower costs. They’ll win the contracts you can’t bid competitively because your overhead is too high.

But this transformation extends beyond routing alone. The most successful contractors build complete systems where operations, customer communication, and growth work together seamlessly. When your field service management platform integrates with marketing and lead generation tools, you create an ecosystem where website visitors become scheduled jobs automatically, completed jobs trigger review requests immediately, and satisfied customers receive follow-up communications that drive repeat business—all without manual intervention.

Ready to stop leaving money on the road? Start this week:

- Track your baseline: Log one week of travel time, mileage, and completed jobs per technician

- Calculate your opportunity: Use the ROI framework in this article to estimate your potential gains

- Identify your biggest routing inefficiencies: Where is time being wasted? What patterns emerge?

- Explore routing software FSM options: Look for platforms offering AI optimization, real-time recalculation, and mobile-first design

The investment is minimal compared to the returns. The implementation timeline is measured in weeks, not months. And the competitive advantage—the ability to complete more work, serve customers better, and operate more profitably than competitors stuck in manual routing chaos—compounds every single day.

Your technicians will spend less time in trucks and more time doing the skilled work they were hired for. Your dispatchers will spend less time firefighting schedule disasters and more time on strategic coordination. Your customers will experience consistently reliable service. And your bottom line will reflect what happens when technology eliminates waste and amplifies productivity.

The question isn’t whether you need routing software FSM. It’s whether you can afford to keep operating without it.

Frequently Asked Questions

What exactly is routing software FSM and how does it benefit a small contractor in Twin Falls?

Routing software FSM (field service management) is an AI-powered platform that optimizes how technicians travel between job sites. It analyzes multiple factors—job locations, technician skills, traffic conditions, appointment windows—to create the most efficient routes possible. For Twin Falls contractors, this means technicians spend 15-25% less time driving and complete 1-2 additional jobs daily. The system automatically adjusts routes when schedules change, ensuring your team always takes the most efficient path between Jerome, Burley, Kimberly, and surrounding areas.

How much travel time reduction can a field service business expect using AI scheduling field service tools?

Industry research shows that field service organizations implementing AI scheduling typically achieve 15-25% travel time reduction, with some operations seeing gains as high as 30%. For a technician currently spending 10 hours weekly driving, that’s 1.5-2.5 hours recovered—enough for 1-2 additional service calls. Research from Kirona demonstrates that reducing travel time by just 10% per day can increase productivity by one additional job daily, translating to $75,000-$125,000 in additional annual revenue for a small contractor with three technicians.

Can routing optimization really increase technician productivity when servicing rural areas like Southern Idaho?

Yes—rural operations actually benefit more from routing optimization than urban ones. In rural Southern Idaho, where jobs might be 15-40 miles apart between Twin Falls, Jerome, Burley, and outlying areas, poor routing creates massive inefficiencies. Smart sequencing that minimizes backtracking can reduce daily mileage by 30-40% while enabling technicians to complete the same work in significantly less time. The key is intelligent clustering: grouping nearby jobs together and creating logical geographic progressions rather than bouncing back and forth across territories.

What kinds of travel cost reduction metrics should I track for my service company in Jerome or Burley?

Track these five essential metrics: (1) Average daily mileage per technician, (2) Fuel costs per technician per week, (3) Average travel time as percentage of total work hours, (4) Number of jobs completed per day per technician, and (5) Cost per completed job including travel expenses. Baseline these metrics for 2-3 weeks before implementing routing software FSM, then measure weekly to confirm improvements. Target 10-15% fuel savings and 15-25% travel time reduction within 90 days of implementation.

How does AI scheduling field service differ from traditional scheduling methods?

Traditional scheduling is reactive and manual: jobs are assigned chronologically as they come in, dispatchers use basic logic (who’s closest? who’s available?), and changes require phone calls and mental recalculation. AI scheduling is proactive and dynamic: it analyzes thousands of potential schedule combinations simultaneously, considering dozens of variables (skills, traffic, job duration, parts inventory), automatically adjusts routes when situations change, and learns from historical data to make increasingly accurate predictions. The difference is like comparing a paper map to GPS navigation that automatically reroutes around traffic.

Is routing software FSM hard to adopt for a small business with only 2-3 technicians?

No—modern routing software FSM is designed for small businesses and typically requires just 2-3 weeks for full implementation. Start with a pilot period where one technician uses the system while others continue manual methods. This proves ROI with minimal risk. Most platforms offer intuitive mobile apps that technicians can master in 1-2 days of actual use. The bigger challenge isn’t technical adoption—it’s organizational: ensuring your team understands why you’re changing processes and how it benefits them (less time stuck in trucks, more predictable schedules, higher earnings potential).

How soon can I see improved margins after implementing routing optimization in my Twin Falls service business?

Most contractors see measurable improvements within the first 30 days. Your technicians will complete 1-2 additional jobs weekly almost immediately as routes become more efficient. Fuel savings appear on the next monthly bill. The full financial impact—20-30% productivity gains, reduced overtime, ability to take on more work without hiring—typically materializes within 90 days. For a three-technician operation, expect $150,000+ in additional annual revenue and $8,000-$10,000 in reduced fuel costs. The ROI timeline is remarkably fast because you’re eliminating waste that was happening every single day.

What are the common pitfalls when seeking tool stack optimization in field service operations?

The biggest mistakes are: (1) Choosing routing software that doesn’t integrate with your existing systems, creating new data silos instead of eliminating them, (2) Implementing too many changes simultaneously, overwhelming your team, (3) Not tracking baseline metrics before implementation, making it impossible to prove ROI, (4) Selecting platforms without proper offline functionality for rural areas with spotty cell service, and (5) Treating the software as set-it-and-forget-it rather than continuously optimizing based on real-world performance. Start with clear goals, pilot before full rollout, and choose platforms designed to work together from the start.

How does travel time reduction impact customer satisfaction and reviews for contractors in Southern Idaho?

Travel time reduction directly improves customer satisfaction in three ways: (1) More accurate arrival time estimates because schedules reflect realistic drive times rather than optimistic guesses, (2) Less rushed service because technicians aren’t constantly running late trying to make impossible schedules work, and (3) Faster emergency response because dispatchers can instantly identify which technician can reach the customer quickest. Field service research shows that on-time arrival rates are among the top factors influencing customer reviews. When your Twin Falls HVAC company consistently arrives within the promised window—unlike competitors who routinely run 30-60 minutes late—your reviews reflect that reliability.

Does routing software FSM integrate with other systems like CRM or invoicing platforms, and why is that important?

Yes—quality routing software FSM integrates with CRM, invoicing, payment processing, and customer communication platforms to create unified business systems. This integration is critical because disconnected tools create the exact inefficiencies you’re trying to eliminate: manually re-entering customer data, leads that don’t sync to scheduling, invoices that require separate processing. The most effective approach combines operational platforms like FieldServ AI (handling scheduling, dispatch, and job management) with marketing systems like LeadProspecting AI (managing lead capture, customer communication, and online presence). When these systems work together, website inquiries automatically become scheduled jobs, completed work triggers immediate invoicing and review requests, and your entire business operates as an integrated ecosystem rather than a collection of disconnected apps.